Contact Us

Fax: USA 1-800-886-7379

China 086-21-63757266

Phone:086-21 63757728/

63757326 / 63757327

61021102 / 61028530

Email: contact@china-synergy.org

It is especially suitable for hollow parts, parts with low residual stress (no stress corrosion) and thick walled parts. Parts with negative slip-angles (undercuts) can be made as well.

However, it requires long cycle time, maybe about two hours. That¡¯s partially why rotational molding suits for Chinese factories.

However, it requires long cycle time, maybe about two hours. That¡¯s partially why rotational molding suits for Chinese factories.

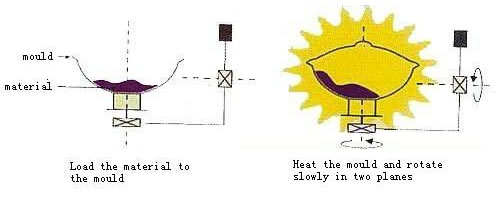

Rotational molding is a Four-stage, no-pressure, plastic molding process.

1. First, the required amount of plastic material is poured into the mould which is then closed.

2. During the heating stage, the mold slowly rotates in two planes (bi-axial rotation). Heat transfer causes the plastic charge inside the mold to melt and uniformly coat the interior of the mold.

3. During the second stage, the mold moves to the cooling station, where it is cooled by air and/or water spray.

4. In the final load/unload stage, the part is removed from the mold and a new charge of material is loaded into the mold

1. First, the required amount of plastic material is poured into the mould which is then closed.

2. During the heating stage, the mold slowly rotates in two planes (bi-axial rotation). Heat transfer causes the plastic charge inside the mold to melt and uniformly coat the interior of the mold.

3. During the second stage, the mold moves to the cooling station, where it is cooled by air and/or water spray.

4. In the final load/unload stage, the part is removed from the mold and a new charge of material is loaded into the mold

Children¡¯s Playground

Containers

Road Traffic products

Rotational molding technology is expanding the capabilities of polymer product manufacturers by enabling them to create light-weight, seamless, stress-free parts of virtually any size in the most complex shapes.

Rotationally molded products represent a wide range of materials, performance characteristics, colors, surface textures and finishes.

The products can be custom-designed to meet precise market requirements more economically than by conventional injection or blow molding.

Rotationally molded products represent a wide range of materials, performance characteristics, colors, surface textures and finishes.

The products can be custom-designed to meet precise market requirements more economically than by conventional injection or blow molding.